|

|

| | GLF iprotect® Filter Series - Monday, November 4, 2019 Parker’s Hydraulic and Industrial Process Filtration EMEA Division is pleased to announce the product launch of the complete GLF iprotect® Series Tanktop return Line Filter Series.Following the introduction of the GLF sizes 2 and 3 in 2018, today we can present the complete 1 to 5 size range.

The Parker GLF iprotect® is designed with the iprotect® patented filtration technology, to provide high quality filtration to hydraulic systems, providing new possibilities to reduce the cost of ownership by improving the productivity and profitability.

• Guaranteed quality of filtration

• No recontamination of the system during the change of the element

• Reduce energy consumption by filter head

• In-Tank mounted solutions are possible

• Maximum performance with less weight and smaller envelope needed

• Reduce service time for the filter with 50%

• Unique OEM branding is possible on request

GLF Series return filter brochure GLF Series return filter brochure |

| | Icount OS with WiFi - Monday, February 2, 2015 Parker’s IcountOS – Now available with WiFiParker is pleased to introduce the icount Oil Sampler with WIFI.

With the WIFI option now being made available, you can operate the IOS from remote locations, transfer data straight to other devices including laptops and computers.

It implicates you can access and share real-time data and analysis instantly, saving valuable time and maximizing control.

IcountOS WiFi brochure IcountOS WiFi brochure |

| | New low pressure switches - Thursday, January 29, 2015 Parker’s new Low Pressure Switches – Offering new featuresParker HIFE-HLF is pleased to announce the introduction of a new range of low pressure switches.

This new range offers extended possibilities related to the connector types like Deutsch and AMP Junior timer, reducing installation time and cost for OEM's and machine builders.

LPS Low Pressure Switches brochure LPS Low Pressure Switches brochure |

| | Distribution Products & Services - Sunday, November 23, 2014 Parker Hydraulic and Industrial Process Filtration EMEA Division introduces a new stock programme initiative for Parker Distributors.Parker's global network of distributors continue to provide their customers effective local coverage and accessibility to the range of filtration and condition monitoring products.

To maintain their lead in an ever-changing industrial environment; Parker has shortened the lead time of a range of key filtration and condition monitoring products identified as the HFDE500 product programme.

This range covers a popular variety of:

• Hydraulic filters

• Lubrication fluid filters

• Portable filtration systems

• Condition Monitoring equipment

• Reservoir equipment

• Flow meters

• Par<>Fit replacement filter elements

This unique one-stop-shop concept has been introduced to further support customers and end users of Parker products and to anticipate further changes and needs for industry in general related to product availability and the opportunity to minimize local product inventories.

Parker Distribution Overview brochure Parker Distribution Overview brochure |

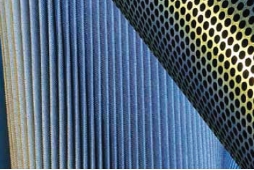

| | SmaRT1000 Par<>Fit addition - Monday, August 25, 2014 Parker expands Par<>Fit range with SmaRT1000Parker is pleased to introduce SmaRT1000 as the latest expansion of the Par<>Fit range. With this expansion Parker offers substitutes for the Pall SRT UE219, 319 and 619 Series.

Thanks to our Static Control technology, the Parker quantumfiber media ensures that the electro-static charging of the oil is kept to an absolute minimum.

Our global network of Parker distributors and sales subsidiaries ensures easy access to our Par<>Fit range.

SmaRT1000 ParFit brochure SmaRT1000 ParFit brochure |

| | Marine engine gas filtration update - Tuesday, April 22, 2014 Parker HIFE-HLF takes the lead in marine engine gas filtration solutionsParker HIFE-HLF recently participated the Marine Propulsion & Auxiliary Machinery Conference in Londen, presenting filtration solutions for gas and Dual Fuel engines.

The usage of gas as fuel for marine engines is expected to grow significant in the nearby future. To maximize engine efficiency and reduced fuel consumption, quality filtration of the gas is essential.

We are pleased to present our capabilities in our gas filtration compentence brochure.

Filter Solutions for Dual Fuel and Gas Engines Brochure Filter Solutions for Dual Fuel and Gas Engines Brochure |

| | SFBO - The new single fuel filter - Wednesday, April 2, 2014 Parker’s SFBO diesel fuel filter – meeting new legislation for the marine and power generation marketsEfficient diesel pre-filtration and water separation for flows up to 90 L/min and a 10 bar max. working pressure

Inspection bodies, prior to the release of new equipment, are particularly concerned about the fireproof design of components used for ships and industrial power generation equipment. IMO (International Maritime Organization) state in their standards that the housing of filters should be made of steel or other equivalent material with a melting point above 930°C.

The SFBO is a robust in-line filter utilizing a cast iron head and steel bowl. The manifold type ensures a compact and reliable mounting to the engine. Manually operated valves for venting and draining are part of the standard product specification.

The diesel pre-filtration and water separation is achieved by incorporating the Parker family of fuel filter media which are available in 1, 5, 10 and 25 micron.

SFBO single fuel filter brochure SFBO single fuel filter brochure |

| | Cleanliness Services - A clean start - Tuesday, January 28, 2014 Parker’s portfolio of cleanliness services is beneficial for introducing control of component cleanliness and in-depth verification of the condition of filter elements and hydraulic fluids.Services that are supportive when considering to implement condition monitoring technologies.

Profitability starts with the cleanliness of system components. A new ISO standard represents a global accepted way to validate the cleanliness of components, saving time and money by reduced system flushing procedures once effectively introduced in assembly departments and manufacturing lines. Parker supports the measurement of individual system components with reporting in accordance to the latest standards.

Before investing in particle counters, used as continuous or temporary tool to validate the oil’s cleanliness level, potential users struggle with the question what oil analysis represents to lower the cost of ownership. The Parker cleanliness services is a convenient way to learn about the benefits of oil analysis. At any time, once particle counters are used and strange aspects are measured, Parker offers a helping hand for a in-depth oil analysis. Another example of extended support is to tailor the performance of filter elements. Parker offers the service to investigate their remaining life time, proven to be very useful when designing new systems.

Cleanliness Services - A clean start is essential brochure Cleanliness Services - A clean start is essential brochure |

| | Parker’s NEW Fluid Property Sensor - Tuesday, January 21, 2014 A NEW addition to Parker Hannifin’s Condition Monitoring range - the Fluid Property Sensor has been designed especially for mobile applications calling for cost effective but quality verification of the hydraulic fluid condition.• A unique solution for continuous monitoring of fluid condition

• Improving uptime of equipment and lowering the cost of ownership

High cost of ownership is caused by the aging of hydraulic fluids, which accelerates the wear of system components. Modern systems are designed to operate at a high level of efficiency and reduced consumption. As a consequence, more frequent fluctuations of pressure, flow, load and temperature are present in the system which typically shortens the life time of hydraulic fluids. Catalytic processes can be accelerated with the presence of low concentrations of moisture and wear elements like Fe and Cu in the oil. Varnish can be created in the system due to this aging process, shortening the life time of system components and reducing the system efficiency.

Lower cost of ownership can be realized when hydraulic fluids are replaced in time, based on the principle of continuous measurement of the condition.

The FPS is a novel fluid property sensor that directly and simultaneously measures the viscosity, density, dielectric constant and temperature of fluids. The quality of hydraulic fluids is determined by monitoring the direct and dynamic relationship between multiple fluid properties.

FPS Fluid Property Sensor brochure FPS Fluid Property Sensor brochure |

| | NEW Metal Wear Debris Sensor - Wednesday, January 15, 2014 A NEW addition to Parker Hannifin’s Condition Monitoring range - the second generation Metallic Wear Debris Sensor - has been designed especially for applications calling for continuous detecting and trend measurement of metallic wear debris.The Parker Kittiwake Metal Wear Debris sensor measures particles sizes from 40 micron to over 1000 micron. Using proven inductive coil technology, it enables continuous measurement of metallic wear debris in hydraulic and lubrication systems. Smart algorithms provide information about the particle size distribution count, differentiating between ferrous and non-ferrous wear particles. Our DebriScan software puts the user in control by offering a customized communication between the metal wear debris sensor and main system controller.

• A unique solution for continuous monitoring of presence and trend development of metallic wear debris in systems

• Effective integration of metallic wear particle detection contributes to avoid unexpected system failure

Metal Wear Debris Sensor brochure Metal Wear Debris Sensor brochure |

| | New brochure on ParFit elements - Monday, October 14, 2013 Parker is pleased to present the lastest ParFit brochure.Whatever the application or market, there's a ParFit solution that fits the job; quickly and efficiently.

With over 50,000 interchange filter elements, covering almost every main OE part, ParFit fits every customer need for specification, reliability, availability and price.

As a global partner for filtration and condition monitoring we are pleased to support your after market service business.

New ParFit brochure New ParFit brochure |

| | Introducing the icount Oil Sampler - Friday, August 16, 2013 Parker Hannifin has enhanced its range of icount online particle detectors with the introduction of an innovative new self-contained and portable device for measuring the quality and cleanliness of hydraulic oils and hydrocarbon fuels.Called the icountOS (Oil Sampler), this new competitively priced system incorporates a laser detection particle counter, battery and pump into a single integrated unit for the real time condition monitoring of fluids, thereby helping maintenance engineers to maximise productivity and extend system life.

The icountOS provides a compact, simple to setup and easy to use solution for providing an immediate warning of particle and moisture contamination in fluids, allowing remedial action to be taken quickly before system degradation or failure occurs.

Available in three versions, for monitoring the quality of hydrocarbon fuels, and either offline or inline oil sampling, the new system is built to ISO standards and uses proven Parker laser particle detection to produce extremely accurate and repeatable results.

IcountOS brochure IcountOS brochure |

| | Parker’s NEW GMF Medium Pressure Filter - Monday, July 15, 2013 Parker is pleased to introduce the GMF iprotect® Series, designed especially for applications calling for cost effective but quality filtration solutions. The GMF applies, like the EPF high pressure filter series, the patented iprotect® filter element.

The new GMF features Parker’s iprotect® family of filter elements representing the next generation of patented filter elements for three readily defined reasons:

1. Thanks to the patented construction of every iprotect element, the quality of filtration is guaranteed, as no ‘pirate spare parts’ can be used. This ensures that the iprotect® element remains the truly protective ‘DNA’ of hydraulic & lubrication systems.

2. In addition to the ultimate protection of the system, the iprotect® family ensures that any environmental impact is minimised, by the retention and re-use of the filter element support core.

3. Finally, iprotect® helps protect the environment by reducing environmental waste, typically by 50%.

GMF medium pressure filter brochure GMF medium pressure filter brochure |

| | The upgrade of a Parker Hannifin’s filter series - Tuesday, June 25, 2013 Parker Filtration is pleased to introduce the upgraded Maxiflow Series.The Maxiflow Series spin-on filters are designed for suction and return line filtration applications, calling for a quality protection against contamination.

Rated at a maximum pressure of 10 bar at 360 l/min, the Maxiflow Series cover a wide range of mobile and industrial applications.

New Maxiflow brochure New Maxiflow brochure |

| | Introducing a tailored system solution - Friday, June 7, 2013 Parker is pleased to introduce a tailored condition monitoring system solution for mobile applications.Modern mobile equipment is very often a dedicated engineered construction including multiple systems for driving, steering, braking and working hydraulics.

The more stringent demands related to the up-time and productivity of mobile equipment results into growing interest for system condition monitoring solutions.

With contamination still accountable for over 80% of the failure of hydraulic and lubrication systems, Parker’s new innovative approach offers a lower cost solution for the efficient monitoring of multiple hydraulic and lubrication systems.

Parker’s Multi System Sampling Island includes a set of sensors and particle counters complete with a manifold incorporating solenoid valves, optional controller and pump to sample oil from different systems.

System after system, the cleanliness level, wear debris, moisture level and fluid condition / aging can be measured. Real time alarms can be raised and information can be transmitted to machine operators, fleet owners, OEM service organizations or the OEM itself. This approach contributes to reducing the unexpected standstill of mobile equipment and supports the introduction of predictable maintenance.

The Multi System Sampling Island is a tailored system solution available on request.

Multi System Sampling Island brochure Multi System Sampling Island brochure |

| | Introducing the new icountBSplus Bottle Sampler - Monday, March 4, 2013 Parker is pleased to present the new icoµntBSplus.

The plus behind the icoµntBS name indicates something is new.To get prepared for future market expectations, Parker has developed the 2nd generation of the icoµntBS providing a more simplified and more effective product to validate the cleanliness level of hydraulic and lubrication fluids.

The icoµntBSplus offers now:

• 11 languages to support the easy and convenient touchscreen guidance

• CE certification

• Optional on-line measurement capability

The plus behind the icoµntBS name represents more value. But please allow us to explain that plus refers also to time.

Fortunately industry focuses most significantly on the importance of a system’s fluid cleanliness level. But, still today, many businesses are using oil bottle samples for validating the cleanliness level by external laboratories. Why lose precious time as the use of external laboratories implies a delay typically of 3 days or more?

plus also means being on time to avoid unnecessary damage to system components and oil. Using the icoµntBSplus, it provides direct results of the fluid cleanliness level and there is no need to lose precious time in initiating actions to stop the ‘wear & tear’ process to the system.

IcountBSplus brochure IcountBSplus brochure |

| | Parker extended large flow capacity filters - Thursday, February 21, 2013 To meet the industrial market need for larger flow capacity filters, Parker has introduced the HFS and HFD Series.Covering a flow rate over 11,000 l/min, the HFS and HFD represents an effective solution for single and duplex filter arrangements for stringent markets like Marine and Power Generation.

To safeguard the quality of filtration, Parker’s iprotect® technology ensures that the use of pirate type filter elements are avoided. Besides the filter element technology, the HFS and HFD Series offers more.

The design of the HFD duplex filters is based on easy but safe operation. The change-over valve is operated by one handle to ensure a synchronized operation of the two butterfly type valves. The duplex filter is equipped with an equalizing line to ensure excessive pressure peaks in the filter housings during the filter change-over process. The filter vessel is optional supplied with a safety cover, ensuring the pressure in the filter housing is released before the filter housing can be opened.

HFS-HFD Series high-flow filter brochure HFS-HFD Series high-flow filter brochure |

| | A NEW addition to Parker Hannifin’s Air Filter range - Tuesday, January 29, 2013 The Heavy Duty Air Filter (HDB) has been designed especially for heavy duty mobile equipment.Meeting more stringent demands regarding equipment productivity and profitability, it goes without saying that adequate protection of the hydraulic system is essential in today’s contamination conscious industrial world. It is however remarkable that the function of system-matched air filtration for the hydraulic reservoir is often forgotten or at worst ignored.

Mobile equipment at work in construction sites or mines is exposed to stones or other debris potentially falling on the reservoir and as a result, damaging the air filter. As the use of air filters with plastic housings is rather popular, it implies there is a greater risk that these can get damaged. In addition to this, air filters with plastic housings or thin metal caps can get damaged when engineers are climbing on machines for inspection or service events.

The impact of a damaged air filter should not be ignored as it can result in damage to the hydraulic pumps or accelerated ingress of contamination into the oil.

Parker’s HDB is a robust but compact air filter that maintains the filtration function under severe circumstances:

• Robust housing avoids blockage of reservoir vent port

• Avoid pump damage due to cavitation as the HDB limits the vacuum that can be created in the reservoir

• Integrated pressurization valve contributes to improved hydraulic pump efficiency

• Reusable filter housing respects the environment and easy replacement of the air filter element

HDB Heavy Duty Breather brochure HDB Heavy Duty Breather brochure |

| | Kittiwake products complete the Condition Monitoring portfolio - Thursday, November 29, 2012 |

| | Static-Free is a promise difficult to fulfill - Tuesday, September 25, 2012 Parker Static Control Filter Media is an effective solution to reduce the negative impact to hydraulic system sensitivity to electro-static charging of the oil.Electro-static charging of hydraulic fluids can result in the promotion of varnish in systems, reducing its profitability and efficiency. It can also result in dangerous situations developing such as contributing to valve malfunction.

In addition to this, due to the discharge of the electro-static energy, filters or other system components can also be damaged.

Static electricity can occur everywhere in a system.

As a comprehensive manufacturer and supplier of motion and control technology, Parker is one of the few companies who can offer qualified support relating to system analysis and also provide the most effective system components necessary for a specific application.

Parker Static Control Media supports the reduction of static charging of the hydraulic fluid.

Parker Static Control Filter Media brochure Parker Static Control Filter Media brochure |

| | The new compact duplex solution type DF65 - Tuesday, September 4, 2012 Parker Filtration is pleased to announce the availability of the new compact duplex filter type DF65.Parker Filtration has a long history in both the Marine and Power Generation markets. The latest addition to the duplex filter series of products is the DF65, a compact solution for flows up to 800 l/min ideal for applications where available space is at a premium.

In comparison with traditional duplex filters, the Parker DF65 can be mounted both in a horizontal position as well as a vertical installation.

The DF65 can also be specified with the patented iprotect ® filter element to safeguard the system by using quality Parker filter media.

Suitable for a system pressure up to 25 bar, the DF65 is an effective solution for demanding industrial applications such as propulsion systems, turbine lubrication and gearbox lubrication circuits.

DF65 duplex filter brochure DF65 duplex filter brochure |

| | Guide to Contamination standards - Wednesday, August 15, 2012 Parker Filtration is pleased to present the latest edition of the Guide to Contamination.Fluid contamination accounts for over 80% of hydraulic system failure. To achieve profitable operation of hydraulic equipment, knowledge about fluid cleanliness standards is essential.

The Guide to Contamination is aimed at engineers, quality control personnel and technicians involved in contamination control.

This Guide provides useful information for users of automatic particle counters with respect to the relation between raw particle count results and the reporting code numbers of various contamination standards.

Guide to Contamination Standards brochure Guide to Contamination Standards brochure |

| | The new stainless steel filter type EAPF - Thursday, January 19, 2012 Parker Filtration is pleased to announce the availability of the new stainless steel filter type EAPF.The EAPF iprotect® is designed to meet the stringent demands of demanding industrial markets like Oil & Gas and Marine, covering a flow rate up to 120 l/min at 690 bar working pressure.

The patented iprotect® element guarantees the quality of filtration and excludes the use of non-genuine filter elements with unknown filtration performance.

The stainless steel filter housing is provided with a unique and durable coating, avoiding the classic problem of galling with stainless steel parts when servicing the filter.

EAPF-Series brochure EAPF-Series brochure |

| | The NEW PT Series Low Pressure Filter - Friday, April 8, 2011 Parker is pleased to introduce the PT Filter – a new tank top mounted filter designed as a basic but effective filter. Max. 400 l/min, 10 bar.The PT series features a strong patented filter element to protect the aftermarket. The ‘in to out’ flow design avoids re-contamination of the hydraulic system and the PT tank mounted filter features an aluminium filter head and screw-in style filter element. This offers the opportunity to use the filter element as a screw-in style filter for co-polymer reservoir applications.

With a patented design that protects the quality of filtration, the PT filter offers system designers modularity and value for money.

PT-Series brochure PT-Series brochure |

| | Introducing the NEW EPF (Ecological Pressure Filter) Series - Friday, October 22, 2010 Parker's latest filtration technology - iprotect® secures system productivity and profitability.

Parker is proud to present the new EPF (Ecological Pressure Filter) high pressure filter range featuring the iprotect® filtration technology.

High pressure filters fulfil an important function to protect sensitive system components against malfunction and excessive wear and tear due to contamination.

The iprotect technology acts as a protective ‘gene’ in hydraulic systems. With the quality of filtration being secured against piracy and low quality retrofit parts, Parker provides profitable aftermarket opportunities.

The new EPF range of in-line filters, with flow capacities up to 700 l/min at 450 bar cover the majority of modern system installation demands and the unique filter element lock ensures that the filter element stays in the bowl during servicing, reducing the overall space envelope needed to accommodate the filter by up to 50 cm. It also reduces the service time by typically over 40%.

Thanks to the use of re-usable parts the environmental impact is reduced by more than 50%.

This is your opportunity to study the new EPF range of high pressure filters in more detail by downloading this 16 page technical specifications, installation drawings and part number configuration bulletin. Click the EPF-Series brochure below.

For more information on the EPF range or any other hydraulic filtration product, email: filtrationinfo@parker.com

iprotect® EPF-Series brochure iprotect® EPF-Series brochure |

| | The ParFit Concept - Wednesday, August 25, 2010

The ParFit Concept In the past, users of hydraulically powered machinery have been forced to buy replacement filter elements from either the machinery OEM or the filter manufacturer. Customer options have been extremely limited - either relying on the uncertain quality and service on offer from spurious manufacturers or pay top prices for recognised names. Now you have the opportunity to source all replacement elements from one major supplier, at the right price. The Parker name is known throughout the hydraulic industry for quality and service. Parker Filtration have undertaken a substantial investment programme and can now offer a comprehensive range of filter elements, carefully designed to be interchangeable with leading manufacturer's products. Parker Filtration engineers, using the latest technology, have designed and tested the new range of elements to meet stringent performance criteria and dimensional tolerances to ensure that ParFit elements can be specified with absolute confidence. ParFit element features include: - Directly interchangeable with competitor elements dimensional tolerances on length, diameter and sealing surfaces are controlled by stringent quality assurance systems.

- ParFit’s match and often surpass the efficiency of original elements.

- Corrosion resistant end-caps and fully bonded construction for maximum strength.

- Conformity to all relevant ISO standards of manufacture and testing.

- Competitive pricing.

- Full range of quality Parker media allows cost-effective matching of media to application compatibility with most hydraulic and lubrication fluids.

- Worldwide availability through the Parker Distribution Network.

NOW IT’S EVEN EASIER TO SPECIFY PARFIT ELEMENTS. Visit www.parkerhfde.com/parfit Or www.parker.com/parfit And check out the ParFit online element selector for yourself. Our extensive range of ParFit replacement elements represent all that is excellent about Parker Filtration’s manufacturing quality and technical capabilities. ParFit is a comprehensive range of elements, designed to allow discerning users to source all their element requirements from a single, high-quality source. Elements that cover most of Europe’s best known suppliers - replacements that often surpass the quality of the original they are replacing. · Now the most requested Par<>Fit element part numbers are available ex. stock from Parker’s European Distribution Centre in Bielefeld Germany. · Parker Filtration’s quality media ensures maximum efficiency and increased filter life potential. · Filter selection from more than 50,000 interchange references can be made either by competitor name and number or by alpha numeric identification. Advantages: Immediate availability ensures a ParFit element solution every time. · Fitting a genuine Parker replacement element. · A cost-effective solution without compromising quality. · Parker’s ‘value-added’ promise means system integrity is assured. ParFit application opportunities are virtually limitless and include Industrial and mobile hydraulic systems, lubrication systems and most hydraulic applications.

ParFit Profitability ParFit Profitability |

|

|

|